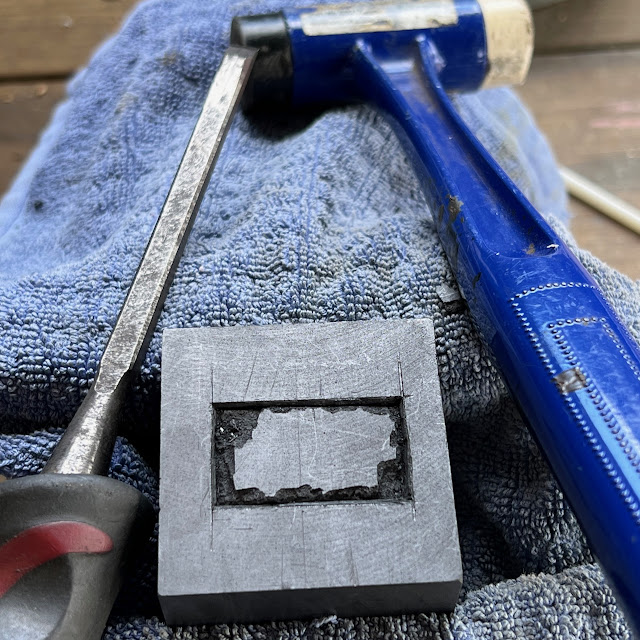

I didn't have buckets loads of time for the shed-workshop today; and I probably was aiming to overachieve!!! Anyway I set myself a few tasks: testing to see how well some pewter I bought from and op-shop would melt; and see if I could carve a wee cottage into a graphite block; and on the very outside see if I could do a pour of the cottage.

From the photo above (bit out of focus) you can see I carved and poured a very rudimentary pewter cottage. A few process photos follow.

I had bought a number of Selangor Pewter mugs from an op-shop - so I did a melt and a couple of pours while I was carving the graphite to see how easily it melted and poured - see below.

One thing I learnt about the pewter ids that it tends to bind to the graphite a bit. The graphite mould might work well if I take the time to smooth a few edges etc in the carving - but that is for next week I think. The cottage is about 32mm long, 20mm high and 19mm wide.

well, this is beyond grand ... I confess to being surprised at how silvery the cottage looks, as I think of pewter as having more of a matte finish unless it is highly polished ... so I'm guessing that may have something to do with the ratios of the metals

ReplyDeletea quick story: back in my Colonial Williamsburg days, I did needlework demonstrations at the James Geddy House, which was primarily presented as an 18th-century foundry site ... while there I got to know the master and journeyman at the time (Sven Dan Berg and Doc Hassel, who then became the master after Dan retired) ... thought you might be interested in this article from twenty years ago that describes the sand casting method they used https://research.colonialwilliamsburg.org/Foundation/journal/Winter03-04/foundry.cfm